Contactez-nous

Micromotors

Applications industrielles

Mentions légales

Demande de devis

Accueil

A propos

Produits en développement

Prestations de recherche

Actualités

![]()

Millions of micromotors in the micromechanical and mechatronic industries require oil lubrication, with oil being applied to extremely specific zones. If parts have not been epilamed, however, the oil ends up spreading across all the surrounding surfaces, which can have several adverse effects:

At Surfactis Technologies, we supply the mechatronics industry and micro-motor manufacturers with a high-performance oil-repellent surface agent that prevents oil spread.

Applying an oleophobic coating enhances oil lubrication efficiency, which in turn helps increase the lifespan of micro-mechanisms and micro-motors as well as reducing friction noise.

Treating mechanical micro-motors with an epilame has a number of major benefits:

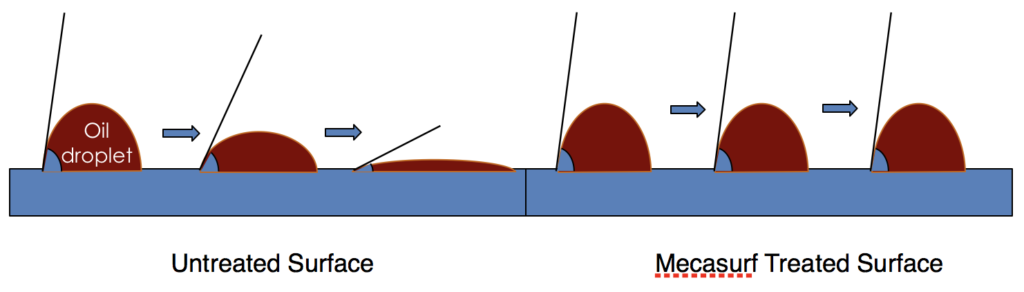

Oil droplets deposited on a surfaced to which Mecasurf has been applied demonstrate no spreading whatsoever and remain anchored to the spot, whilst those deposited on an untreated surface demonstrate spreading behaviour.

Mecasurf’s high-performance anti-spreading properties make it the perfect choice for precision instruments and micro-mechanisms where long lifespan and reliability are crucial:

Hydrophobic Coatings

Mecasurf also imparts hydrophobic properties to the treated surface, which means water is repelled as well as oil. As a result, the treated micro-motor is protected from humidity, lessening the harmful effects condensation, water droplets or the flow of water can have on sensitive parts.

Want to know more about Mecasurf? Click here.